Empower logistics and supply chain efficiency through AI-powered robotics, smart inventory systems, and real-time operational analytics — transforming warehouses into intelligent, self-optimizing hubs.

ByteChrome’s Warehouse Automation solutions combine AI, robotics, and IoT to streamline inventory handling, reduce operational costs, and maximize productivity across logistics networks.

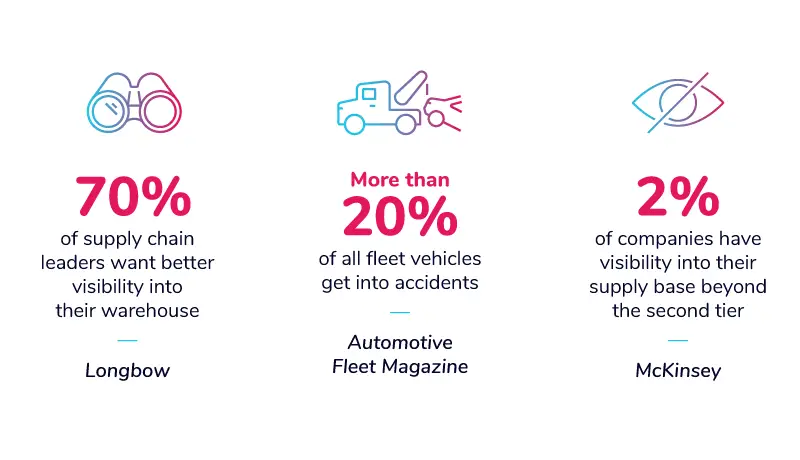

Leverage AI-powered tracking and predictive analytics to manage stock levels efficiently, minimize shortages, and reduce overstocking with real-time visibility.

Automate material flow using robotic arms, AGVs, and conveyor systems — ensuring faster, safer, and more accurate movement of goods throughout the warehouse.

Use machine learning algorithms to identify workflow inefficiencies and automatically adjust warehouse operations for maximum throughput and cost-effectiveness.

Implementing warehouse automation presents challenges in system integration, scalability, data synchronization, and real-time decision-making. Addressing these ensures efficiency, safety, and adaptability in dynamic supply chains.

Integrating AI systems, robotics, and existing ERP or WMS platforms requires high interoperability to maintain real-time data consistency across warehouse processes.

As warehouse demand fluctuates, automation systems must easily scale up or down without disrupting ongoing operations or requiring major reconfigurations.

Coordinating multiple robots and processes simultaneously requires high-speed data processing and AI decision-making for smooth and conflict-free warehouse operations.

Automated warehouses must ensure worker safety, prevent collisions, and maintain reliable system uptime even under high-speed and high-volume operations.

Managing power consumption of automated systems and optimizing workflows for energy efficiency are key sustainability challenges in warehouse automation.

As warehouses rely on IoT and cloud systems, protecting sensitive logistics data and maintaining secure network connectivity is vital for uninterrupted operations.

Empowering manufacturing and logistics businesses with intelligent warehouse automation systems that optimize operations, reduce manual errors, and maximize efficiency through AI, robotics, and real-time data insights.

Leverage AI-driven robotic systems for smart material handling, automated picking, and sorting — enhancing productivity and accuracy in warehouse operations.

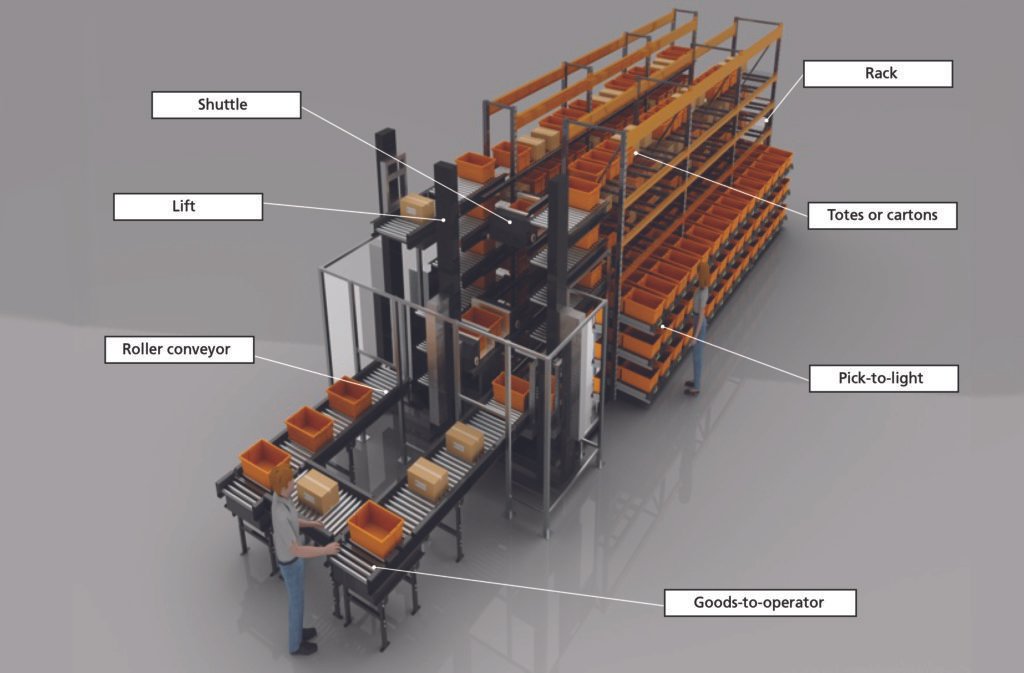

Implement intelligent storage systems that optimize warehouse space, reduce picking time, and ensure precise inventory control.

Gain actionable insights with advanced analytics dashboards that monitor performance, predict maintenance needs, and optimize labor utilization.

Discover how ByteChrome’s Warehouse Automation Solutions revolutionize logistics by improving efficiency, ensuring accuracy, and enabling data-driven operational excellence.

Automate repetitive warehouse tasks to accelerate order fulfillment, minimize downtime, and achieve consistent operational flow.

Track inventory levels in real time with AI sensors and data analytics to prevent stockouts, overstocking, and discrepancies.

Lower labor costs and reduce waste by automating processes and optimizing space utilization across your warehouse operations.

Access real-time analytics and predictive insights that guide strategic planning, resource allocation, and performance optimization.

Reduce workplace accidents and minimize human error through robotic automation, safety monitoring, and precise handling systems.

Scale operations easily with modular automation systems that integrate seamlessly with existing warehouse infrastructure and software.

Transform your warehouse into an intelligent, automated ecosystem. Streamline logistics, enhance efficiency, and stay ahead of demand with data-driven automation.

Learn how our intelligent warehouse automation systems help businesses improve efficiency, reduce operational costs, and achieve real-time visibility across logistics and inventory workflows.