Empowering industries with cutting-edge automation, precision engineering, and intelligent systems — driving efficiency, reliability, and innovation in machinery production.

ByteChrome delivers next-generation industrial automation and machinery production solutions — combining robotics, AI-driven process optimization, and smart maintenance systems to redefine manufacturing efficiency.

Integrate robotic systems and IoT-enabled machinery to achieve seamless automation, reduced downtime, and improved production precision.

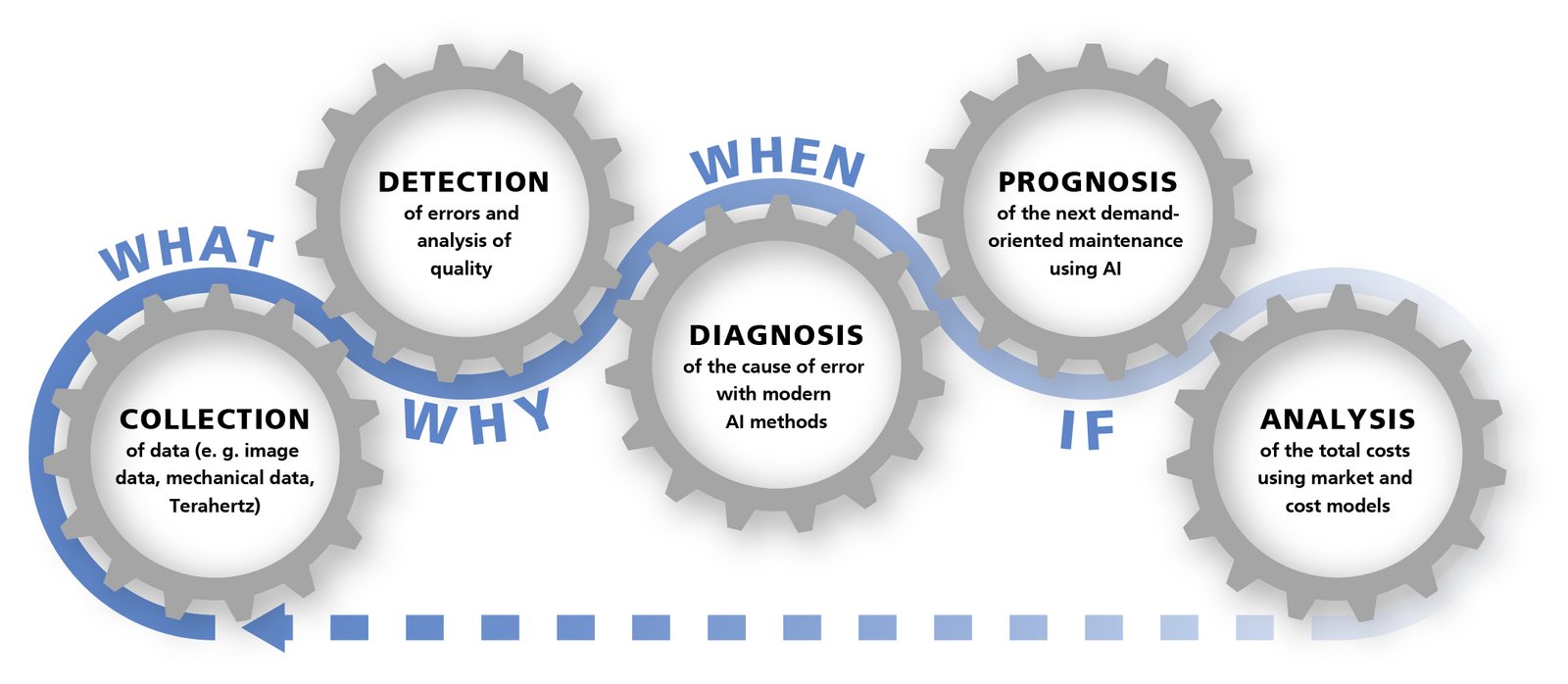

Utilize real-time data analytics and AI predictions to identify wear, prevent breakdowns, and extend equipment lifespan with minimal human intervention.

Optimize energy use and reduce waste through eco-efficient machinery and green production technologies for a cleaner industrial future.

The manufacturing industry faces rising challenges from automation complexity, supply chain disruptions, and demand for sustainable production. Overcoming these barriers is key to maintaining global competitiveness.

Frequent breakdowns can delay production and increase costs. Predictive analytics and IoT monitoring are essential to ensure operational continuity.

Unreliable material supply and logistics delays impact production flow. Adaptive planning systems and digital twins can help mitigate risks.

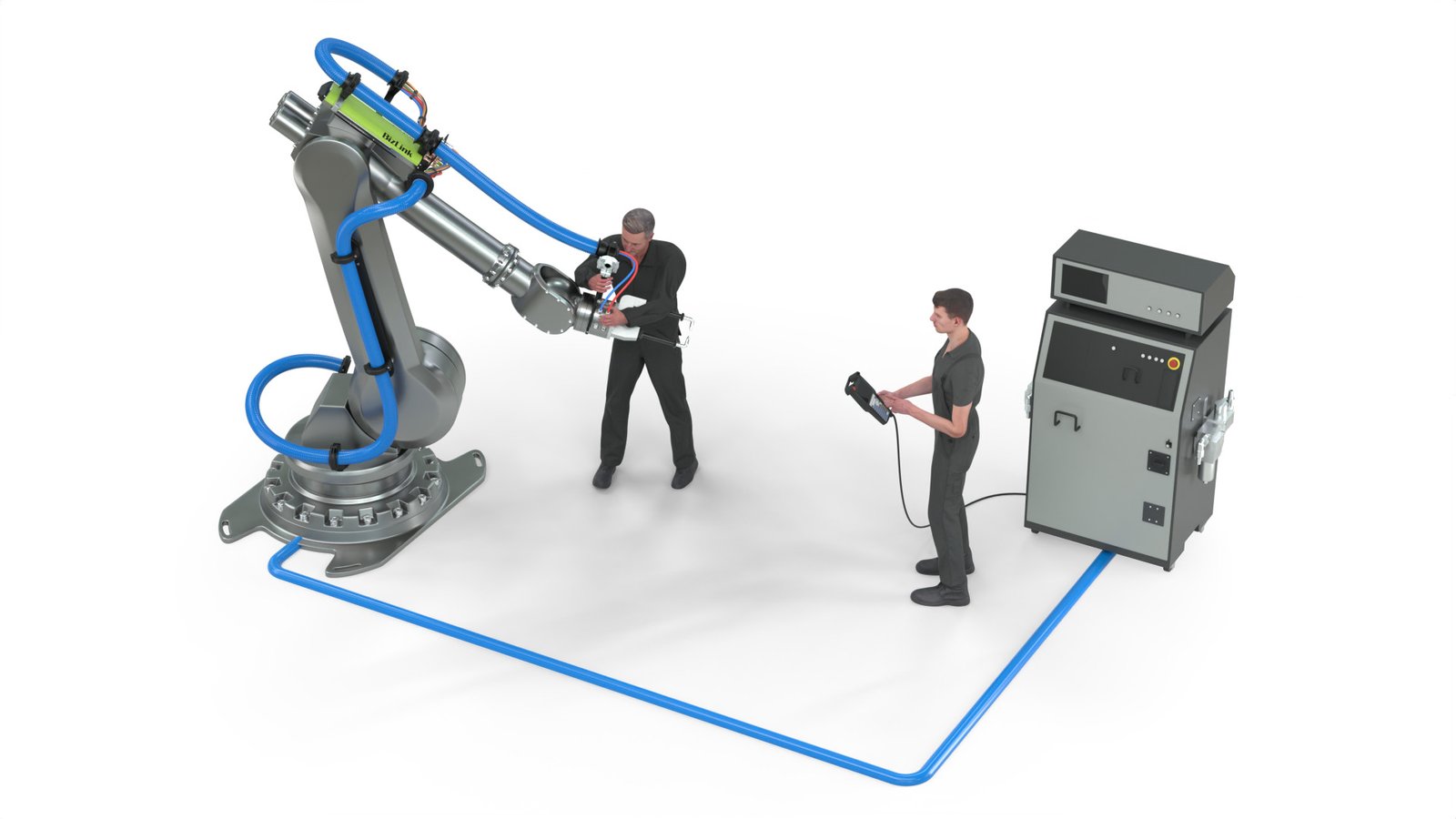

Advanced machinery demands skilled operators and engineers. Upskilling through digital tools and AR-based training is vital for modern production lines.

Rising energy costs and sustainability targets push industries to adopt greener, energy-optimized machinery with minimal carbon footprint.

Older production equipment often lacks digital compatibility. Retrofitting IoT and automation systems can modernize legacy infrastructure.

Maintaining high precision and quality in large-scale production requires real-time monitoring, calibration, and AI-assisted inspection systems.

ByteChrome designs intelligent, automated, and energy-efficient industrial machinery systems — combining robotics, IoT integration, and AI-based analytics to drive precision manufacturing and optimize production efficiency.

Integrate collaborative and autonomous robots for high-speed, precision assembly, improving efficiency and reducing human error across production units.

Enhance production lines with intelligent automation that combines robotics, sensors, and machine learning to reduce downtime and improve manufacturing precision.

Utilize AI and IoT data to predict machinery wear and schedule maintenance before failures occur, maximizing uptime and minimizing repair costs.

Discover how ByteChrome’s industrial machinery innovations transform manufacturing by improving precision, reducing costs, and driving productivity through smart automation and analytics.

Boost manufacturing output through automated workflows and synchronized machinery for continuous, high-speed production lines.

Predict and prevent equipment failures with smart monitoring systems that ensure operational continuity and minimize unplanned stops.

Maintain consistent quality standards using AI-based inspection tools that detect anomalies at every stage of production.

Adopt energy-efficient technologies and smart resource management to lower environmental impact and operational costs.

Gain real-time visibility into machinery performance and production data through integrated IoT dashboards and analytics.

Reduce operational and maintenance costs using intelligent production planning and predictive maintenance solutions.

Upgrade your production capabilities with AI-driven, automated, and energy-efficient machinery systems that ensure precision, reliability, and scalable industrial performance.

Learn how our industrial machinery production solutions enhance manufacturing efficiency, improve equipment reliability, and drive innovation across production lines.