Protect connected production lines, ensure data integrity, and enhance operational resilience with AI-driven cybersecurity and smart digital infrastructure built for modern electronics manufacturers.

ByteChrome empowers electronics manufacturers with AI-driven cybersecurity, smart automation, and data integrity tools to optimize production efficiency and safeguard digital manufacturing ecosystems.

Protect IoT-connected machinery, robotics, and factory systems from cyber intrusions using real-time threat detection and network segmentation technologies.

Leverage AI to analyze production data, detect inefficiencies, and predict equipment failures — ensuring seamless, secure, and cost-effective manufacturing workflows.

Safeguard proprietary designs, firmware, and production data with encryption, blockchain verification, and access-controlled digital systems.

Electronics manufacturing faces growing cybersecurity challenges with the rise of connected factories, smart devices, and global supply chains. Securing data, equipment, and IP across the production lifecycle is crucial for long-term resilience.

Electronics manufacturers face constant threats of IP theft and design leaks. Protecting digital blueprints and firmware from cyber espionage is essential to retain market competitiveness.

Connected production equipment increases the attack surface. Unsecured IoT endpoints can expose manufacturing data and disrupt critical operations.

Cyberattacks targeting PLCs, robotics, and MES systems can halt production, causing downtime, financial loss, and safety concerns.

Global supplier networks are often exploited for data breaches. Weak links in vendor systems can compromise manufacturing integrity and product traceability.

Maintaining secure, verifiable production and quality data across multiple facilities ensures compliance, product reliability, and trust.

Manufacturers must be equipped with rapid incident detection and recovery mechanisms to maintain uptime and protect high-value equipment and data.

ByteChrome empowers electronics manufacturers with intelligent automation, real-time monitoring, and AI-driven quality assurance systems — optimizing production efficiency, reducing costs, and ensuring precision in every component built.

Integrate robotics, IoT sensors, and AI-powered controllers to automate complex assembly lines, improve operational accuracy, and minimize human error in production.

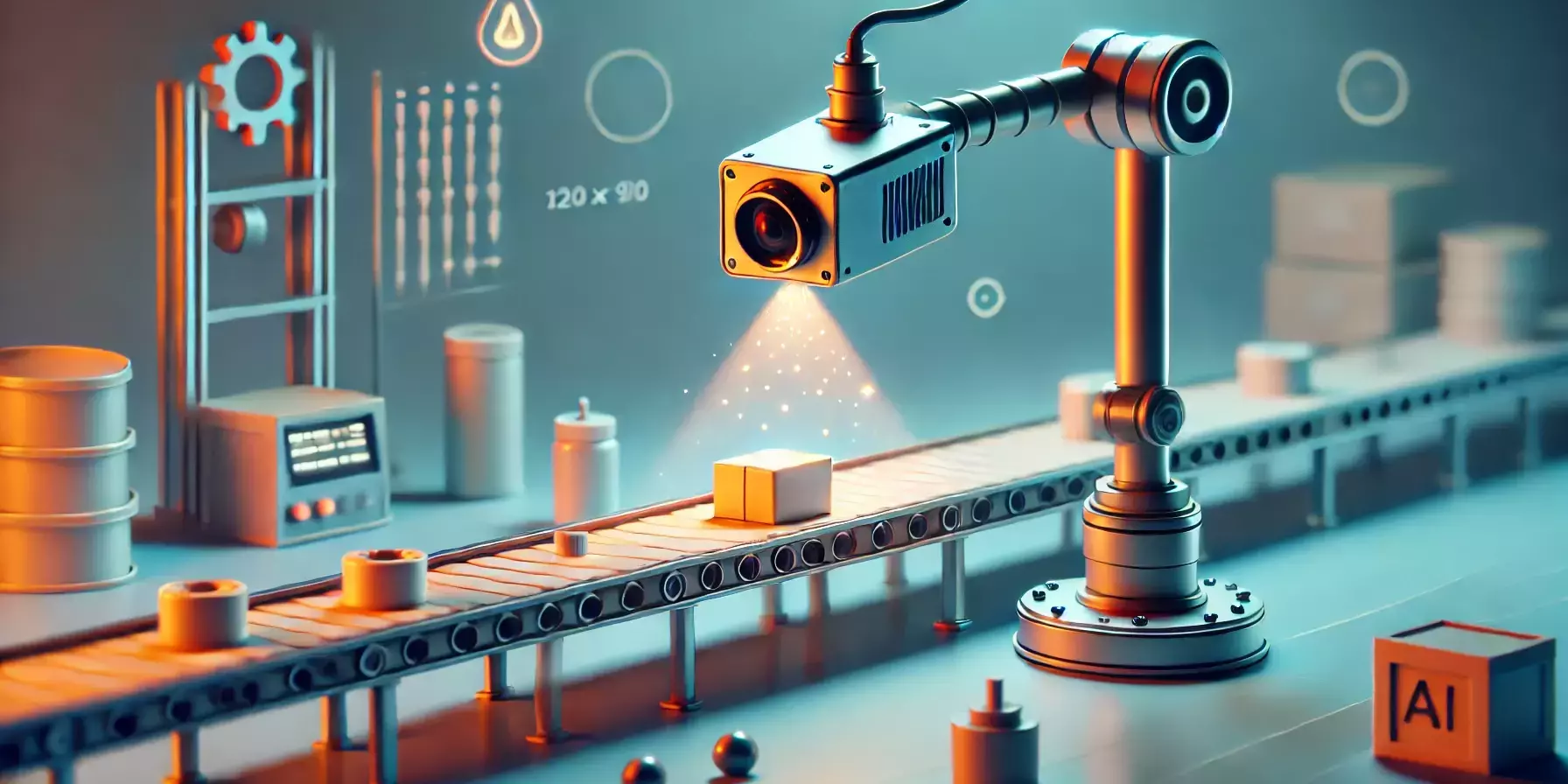

Use computer vision and deep learning to inspect micro-components, detect manufacturing defects, and ensure flawless product quality with real-time analytics.

Enhance traceability, predict material shortages, and optimize logistics through real-time data tracking and AI-based demand forecasting.

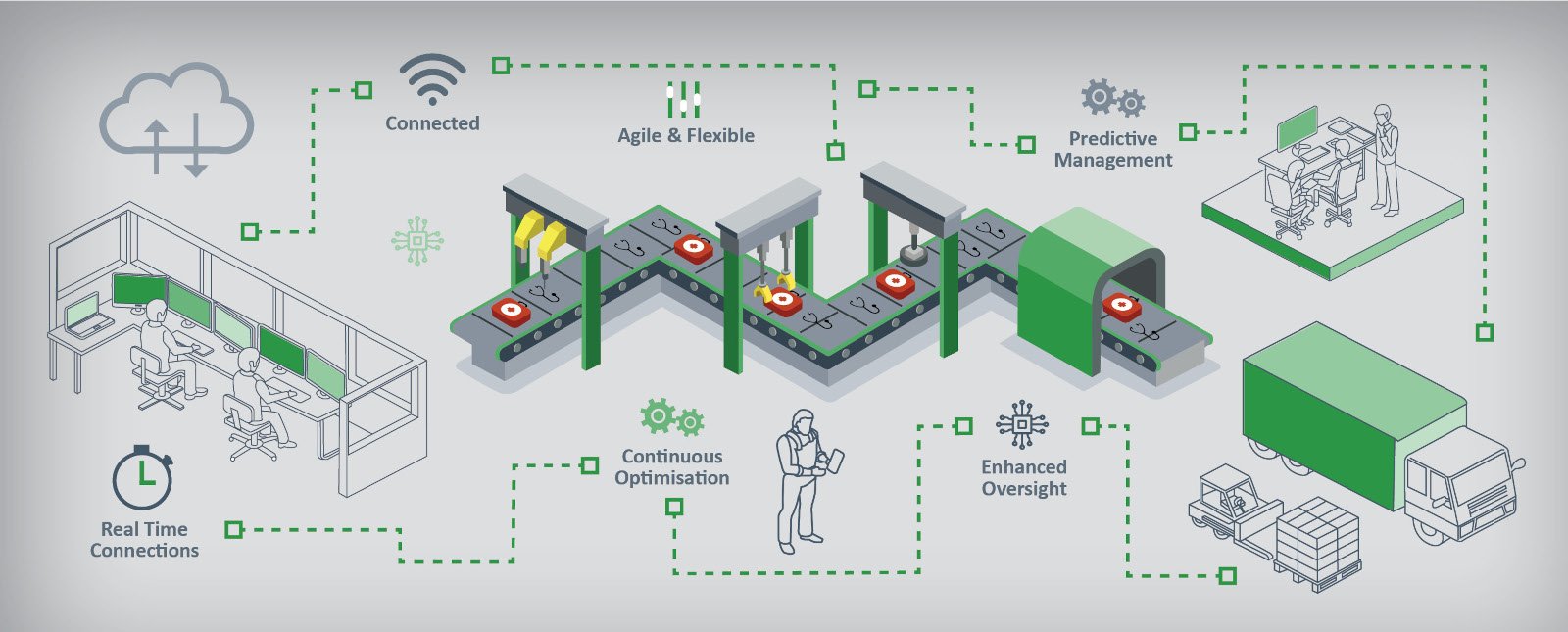

Explore how ByteChrome’s intelligent electronics manufacturing solutions enhance productivity, sustainability, and precision across every stage of production — from design to delivery.

Boost output and reduce production delays using smart scheduling, automation, and data-driven decision-making tools.

Minimize defects and ensure precision assembly with AI-powered inspection and predictive process control systems.

Utilize predictive analytics and IoT alerts to anticipate machine failures and maintain seamless production continuity.

Gain end-to-end visibility across your production ecosystem with digital dashboards and cloud-based analytics.

Reduce waste and energy consumption through smart resource allocation and eco-friendly automation systems.

Accelerate innovation with modular, AI-enabled systems that adapt to new product designs and market requirements effortlessly.

Drive efficiency, precision, and innovation across your production ecosystem. Harness AI, IoT, and digital transformation to redefine your electronics manufacturing processes.

Learn how our advanced electronics manufacturing solutions enhance production efficiency, ensure quality control, and streamline your entire manufacturing lifecycle — from design to delivery.